Thermal Precision in Hot Air Roasting: Why Consistency Starts with Air

Great coffee starts with consistency, and that begins with precise, controllable heat. In specialty coffee roasting, thermal precision isn’t just a nice-to-have, it’s the foundation. From highlighting the delicate florals of a washed Ethiopian to bringing out the lush tropical fruit and cocoa in a natural Sulawesi, it all depends on how you manage heat in the roast environment. That’s where hot air roasting stands out, offering steady, responsive control that lets you shape your roast curve rather than chase it. Here’s why thermal precision in hot air roasting makes all the difference. Let’s dive in!

Why Thermal Stability Matters in Roasting?

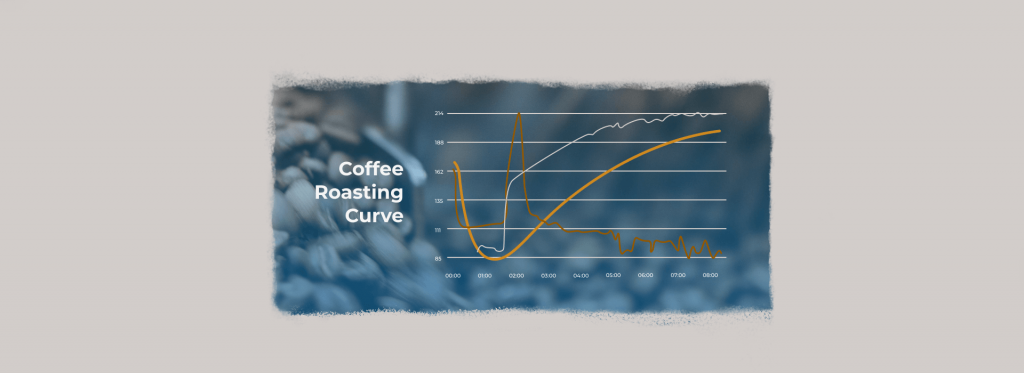

Fluctuations in temperature during roasting can quickly lead to under or overdevelopment. When the heat drops too low at key stages, the beans don’t develop fully, resulting in sour, grassy, or flat-tasting coffee. On the other hand, sudden heat spikes that push the roast too quickly can reduce its characteristic notes, resulting in bitter and smoky flavors. Even when using the same roast settings, factors like leftover heat from a previous batch, a lagging burner, or poor airflow can throw the roast off balance.

Consistent heat flow is what gives roasters the ability to repeat results from batch to batch. Hot air roasting methods are especially helpful, as they respond quickly to changes and maintain even heat distribution throughout the roast. This steady thermal environment lets you guide the roast curve with precision, ensuring that the full flavor potential of the coffee is achieved every time, not just once.

Achieving Thermal Stability with Hot Air Roasting

Hot air roasting or fluid bed roasters are built around one core principle: the convection-based heat transfer. Instead of relying on direct contact with a hot drum, these systems use a steady stream of hot air to surround and heat the beans evenly, resulting in a smoother, more balanced roast.

With less surface contact, hot air roasting reduces tipping and scorching while minimizing external stress on the bean and the risk of common roasting flaws—all of which are more common with traditional conductive drum roasting. This makes it easier to preserve delicate flavors and maintain a clean, balanced result.

Another key advantage is responsiveness. Hot air roasters react more quickly to adjustments in heat or airflow, giving roasters finer control over roast profiling. That shorter response time allows for more precise curve shaping, making the results remain consistent batch after batch.

Thermal Consistency Built into Berto Hot Air Machines

Berto’s hot air machines are designed to deliver thermal consistency you can rely on batch after batch. The Berto Essential Air is designed to maintain a stable airflow environment that is crucial for small batch roasting. The clean and consistent air movement ensures each small batch develops evenly, without the risk of hot or cold spots that throw off flavor.

Berto Type R Roaster machines provide real-time monitoring of roasting temperatures, giving roasters the ability to track heat conditions and make precise adjustments throughout the roast. Its fast cooldown cycles lock in exact roast levels, while rapid profiling capabilities help dial in ideal roast curves with ease. This makes it a strong fit for commercial hot air roasting—especially when flavor precision matters down to the last detail.

Both the Berto Essential Air and Type R feature an advanced sensor system that delivers accurate temperature control, ensuring consistent roasts and repeatable flavor, batch after batch.

Who are Berto Essential Air and Type R Roaster Built for?

Berto roasters with advanced hot air roasting systems are perfect for settings where thermal precision and repeatability matter most. For roasteries focused on quality control at scale, Berto hot air roasting machines’ consistent heat delivery across multiple batches helps maintain tight control over flavor profiles. In labs or competition settings—where even small temperature shifts can affect the results—the system’s thermal stability and real-time monitoring provide the accuracy needed to replicate roasts with precision.

These hot air systems are also ideal when working with high-density or delicate beans, where controlled, even heat application is crucial to avoid under- or overdevelopment. For cafés that need predictable daily output, Berto’s ability to maintain precise heat flow ensures that every batch is as consistent as the last.

Thermal precision in hot air roasting is the cornerstone of achieving consistent, high-quality coffee. With their ability to maintain stable and responsive heat flow, hot air roasting machines like Berto’s Essential Air and Type R empower roasters to unlock the full flavor potential of every batch. Whether you’re a small-batch artisan or running a coffee lab focused on perfect repeatability, these machines offer the control and reliability you need to craft exceptional coffee with confidence.

Ready to elevate your roasting game? Experience how Berto hot air roasting machines can transform your process and deliver unmatched consistency. Don’t wait to taste the difference—contact us today! Our team is here to help you find the perfect solution for your roasting needs.