How are Roast Data Logging Different on Modern Coffee Machines?

With the coffee industry experiencing constant technological advancements, more coffee roasters are investing in modern equipment with up-to-date roasting software. However, let’s keep in mind that transitioning from traditional models to modern coffee machines requires planning and understanding, particularly when redeveloping the coffee roasting data log.

Some experts in the industry believe that traditional roast logs are becoming outdated, especially with the constantly growing specialty coffee sector.

Read on to learn more about how roast logs are changing.

The Traditional Roast Curves

In the past, people tracked roasting variables manually on paper as the beans are being roasted. This was often inconvenient, time-consuming, and prone to error.

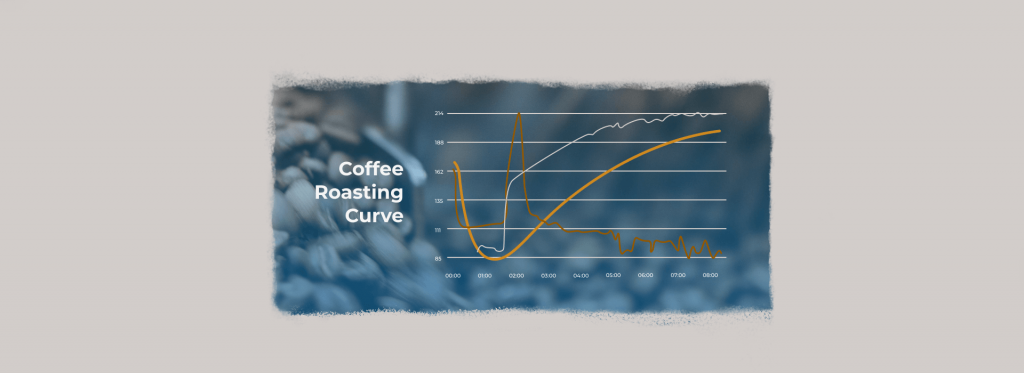

The first point on a roast curve is the ‘charge temperature‘, which is the drum’s temperature before the beans are added. Once the beans are present, a sharp decrease in temperature occurs, followed by a gradual increase. This is known as the ‘turning point’, and this subsequent pattern of temperature increase can be plotted over time to form a curve.

For a roaster to achieve the desired roast profile, the temperature inside the drum must be carefully controlled. The “rate of rise” (RoR) measures the temperature increase, which determines the steepness and speed of the roast curve. As the beans lose moisture and roast temperatures decrease, the curve becomes flatter and steadier towards the end of the roast.

The RoR is a critical variable in roasting, enabling roasters to achieve their desired profile more efficiently.

As roasting technology has progressed, data has become increasingly vital to roasters, including maillard timing, development timing, development time ratio and end temperature.

By analyzing this data, roasters can create more precise roasting profiles, plan necessary changes for the next batches and achieve consistent batches every time, leading many to opt for more modern equipment.

What is a modern coffee roasting machine?

Coffee roasters and roasting equipment have come a long way since the days of thin, perforated pans used over an open flame.

“Modern roasters” can be a broad term. Some may define roasting technologies launched over the past ten years as modern roasters. This includes machines with various heat transfer or automation systems and equipment that uses smart technology to support the roaster.

In recent years, roaster design has placed significant emphasis on software integration. Modern machines often feature sensitive probes that give roasters more accurate information than older equipment.

Manufacturers also incorporate artificial intelligence technology to predict variables like the first crack. In addition, sustainability and energy use have become popular topics in coffee roasting.

While traditional roasters typically use gas for heating, modern machines are becoming more energy-efficient. They use electricity or recycle heat and exhaust fumes to reduce operational costs, leading to greater energy savings.

So, how are roast data logging different on modern machines?

Technological advancements in roasting have enabled roasters to make precise profile adjustments more efficiently. The data produced by modern roasters are easier to interpret, despite the roast curves used on these machines are more detailed and comprehensive compared to traditional data logs.

This removed unnecessary labor and helped roasters focus on their work while making reproducing their results easier.

Roasting software was developed to collect, organise automatically, and pattern roast data. Additionally, roasting software allows roasters in making mid-roast adjustments and predicting outcomes more accurately through live graphing.

Less experienced roasters may find it difficult to understand the differences in roast curves between traditional and modern equipment. Roasting software can help bridge this gap. However, even with more control over roast profiles, it is important for roasters to deeply understand their machines, as each modern coffee machine differs in many ways.

Automated roasting technology and software have developed to become more equipped to keep up with the ever-growing demands of roasters and their customers.

Knowing roast curves is crucial in coffee roasting. This means professionals must understand them thoroughly, whether using traditional or modern equipment.

As more roasters utilize modern coffee machines, ensuring a seamless transition from one to the other is more important than you may think. It’s key for roasters to be able to integrate, adjust, and refine their roast profiles to enhance and maintain coffee quality.

To learn more about the coffee roasting curve, read our blog here.

Looking for a modern coffee roasting machine? Take a look at the state-of-the-art Berto roasters, complete with advanced software.