How We Build Our Coffee Roasters

This is our production facility in Tangerang, West Java. This is where we have been building our coffee roasting machines since 2017. Our team consists of skillful engineers and experienced technicians, automation professionals and coffee experts that work closely together to build the best roasters for your business.

Our journey did not start with coffee.

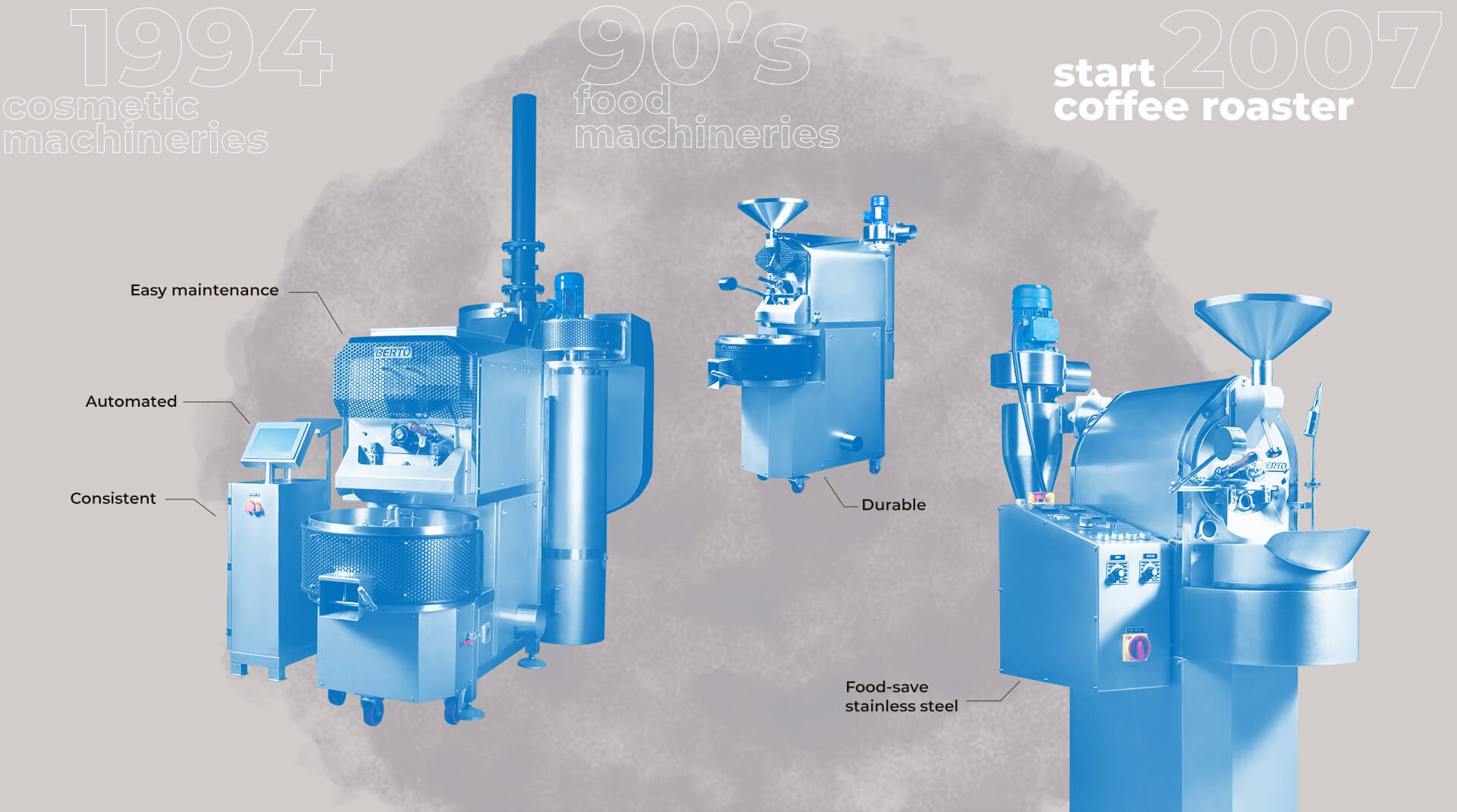

Berto was founded in 1994 by Robert Patilaya as a manufacturer of cosmetic machineries. Some years later, during the 90s we started to focus on food machineries. We were the first company to manufacture specific machineries such as enrober, cooling tunnel, extruder and fryer in Indonesia. For many years we built our machines and exported our products to various countries in South East Asia, Middle East, Australia and Europe.

Then coffee happened on us. In 2007 we built our very first coffee roaster, the 60kg convection roaster. But it wasn’t until a decade later when we decided to merge our technical skills, our experience in building machineries and our passion for coffee into one. We made the commitment to pivot our entire business into the coffee roasting industry.

Each Berto machine takes between 6 to 8 weeks to manufacture, from raw materials to a finished product. All our coffee roasters are made from food-save stainless steel that is hygienic, durable as well as stylish. All products have gone through our high standards manufacturing process, rigorous quality control and testing before we release it to our customers. Our machines virtually need no maintenance aside from regular lubrication for the joints. We also offer two-year warranty for all products. But these aren’t the reason for buying our products.

The reason you should use our product is the fact that when you purchase a Berto coffee roaster, you are getting much more than a roasting machine. You are also getting technology so you can work smarter, not harder. All of our machines are connected to an open-source Artisan software for automated replication, which guarantees the consistency of your roast profiles on every single batch. What you actually need to do is to drop the coffee beans in and collect the roasted beans at the end of the batch. This Curve Control technology really takes the load off your work, as your end product will have a consistent quality regardless of who operates the machine. We understand that for our client, roast profile consistency is paramount.

Berto roasting machines also have other features that are prevalent in our D-Roaster and R-Roaster types:

- Gas leak detector

- Low pressure sensor

- Flame failure detector

- Safe shut down

- Smokeless system (only R-Roaster series)

- Touch screen control (only R-Roaster series)

- 100% hot air heat transfer (only R-Roaster series)

Berto machines simplifies the roasting process

So you can focus on your job: serving great coffee to your customers. With our machines we ensure the roast consistency and roast quality of your beans. Whether you are a small neighborhood café or a prominent coffee distribution company, we believe we have the solution for you. Please feel free to contact us and spill your beans (both literally and figuratively) so we can work together to take your business to the next level.